北京壮仕科技有限公司

OTF-1200X-5-III-SF 5"滑动法兰1200℃三温区CVD系统

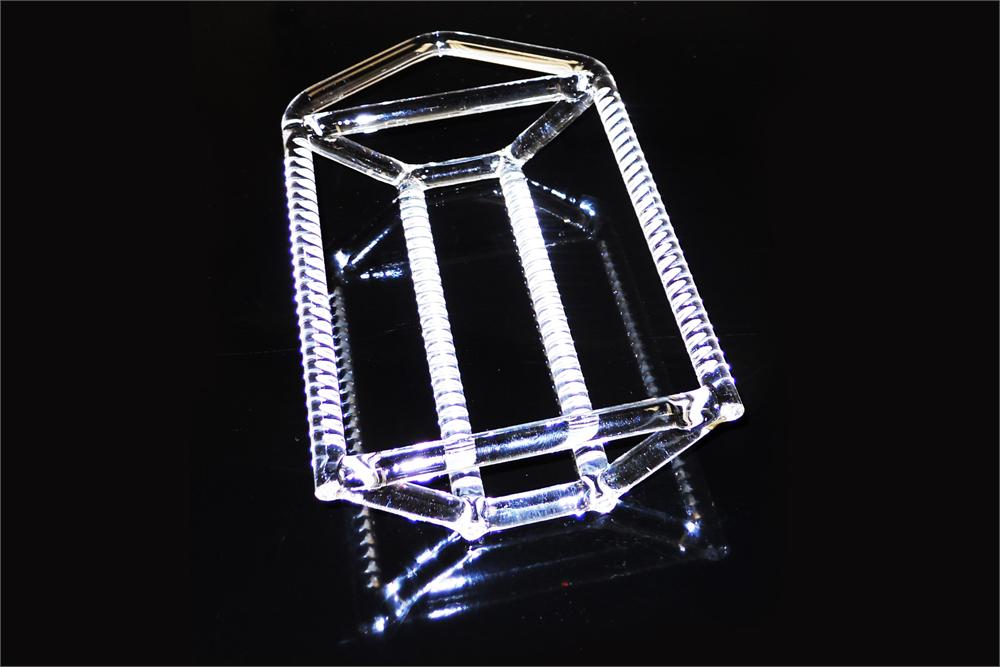

OTF1200X-5-III-SF is a CE certified split 5" (O.D) three-zone tube furnace, which can achieve faster heating up to 1200oC and create a different thermal gradient by adjust three zone temperature. The furnace includes all accessories for immediate use. It is an excellent furnace for annealing, diffusing and sintering sample in various atmospheres.

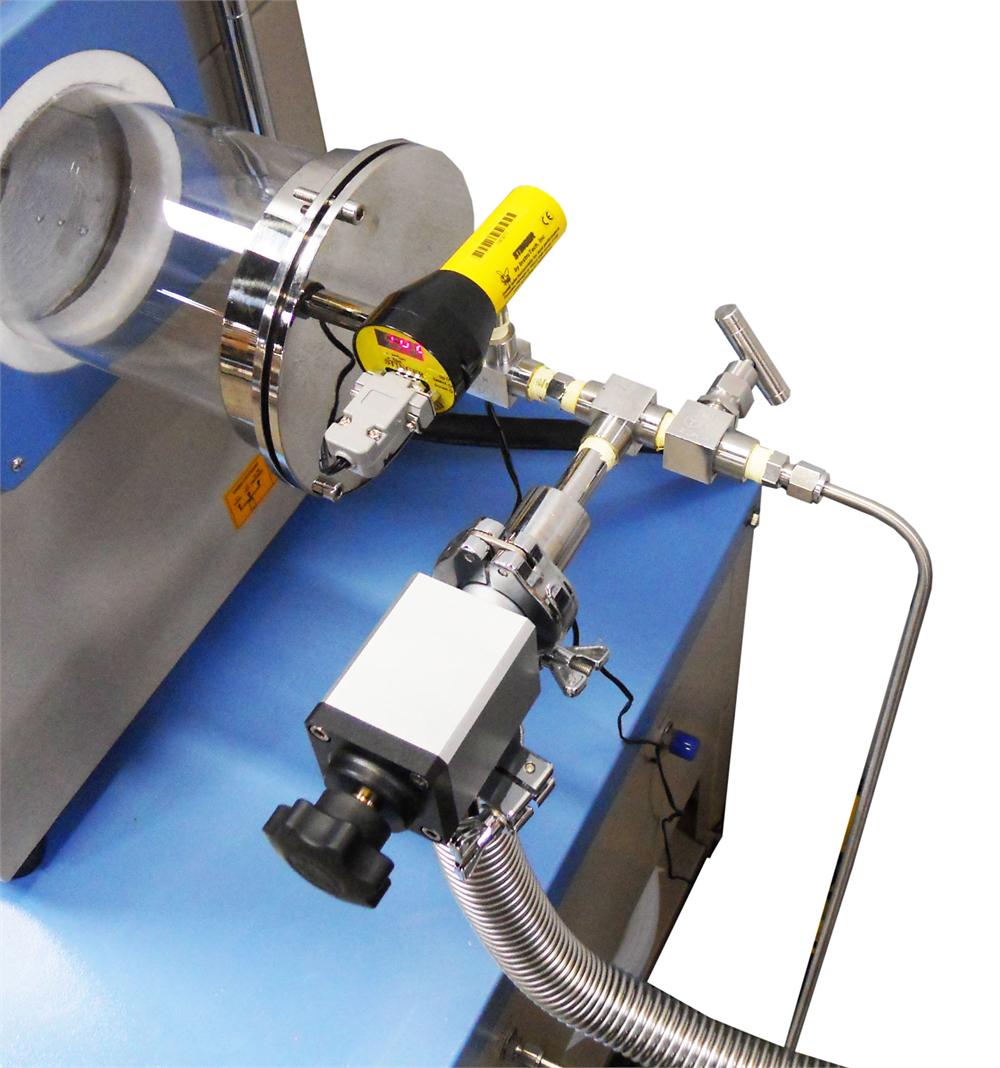

- One 5" O.D x 1400mm L fused quartz tube and one pair of vacuum sealing flanges with pressure gauge;

- Three 30 segments temperature controllers are installed with K type thermal couple. Microprocessor-based self-tuning PID control provides excellent control without overshootingand +/- 1 oC accuracy;

- 800mm long sliding rail is installed with one end flange to make loading & unload sample at easy;

- Two mobile carts are included to support furnace and sliding rail;

- Three flowmeters (range: 0-100 ml/min, 0-160 ml/min, 0-250 ml/min) are installed in one of mobile cart, which allow to use three types of gas during heat treatment;

- One mechanical pump with KF25 adaptor and SS pipe are included with furnace;

- One digital vacuum gauge is installed on the flange for easy vacuum pressure reading upto10 -4 torr;

- Click picture below to enlarge and to see details;

| Specifications: | |

|---|---|

| Furnace structure |

● Double layer steel case with two cooling fan, which ensures low surface temperature ● Energy saving high purity fibrous alumina insulation ● 内炉膛表面涂有美国进口的高温氧化铝涂层可以提高设备的加热效率,同时也可以延长炉膛的使用寿命 ● One flange is supported by sliding rail to make sample loading /unloading easy, and another seal flange is installed with a digital vacuum gauge ● One Double Steps Rotary Vane High Speed Vacuum Pump (240 L/m) with Oil is included. |

| Voltage & Power |

● AC 208-240V Single Phase, 50/60 Hz (40A breaker required) ● Powder cord is included without plug ● 7 KW Max |

| Max. Temperature | 1200℃ |

| Continuous Temperature | 1100℃ |

| Max. Heating Rate | ≤20℃/min |

| Tube Size and Flange |

● 125 mm O.D x 120 mm ID. x 1400 mm fused quartz tube included ● Vacuum flanges with valves and pressure gauge are included. Click picture below to see details |

| Heating Zone Length |

Three zones: (900mm, 36" in total) ● Zone 1: 229mm (9") ● Zone 2: 457mm (18.0") ● Zone 3: 229 mm (9") |

| Constant Temp. Zone |

● If set three zone at same temperature, constant temperature zone is 25" (625 mm) length within +/- 1℃ ● If using one zone (center zone), constant temperature zone is 4.3" (110 mm) length within +/- 1℃ |

| Temperature Controllers |

● Three Digital Controllers, and each has 30-segement ● Built in protection from over-heated and broken thermo couple |

| Temperature Accuracy | +/- 1℃ |

| Heating Element | Fe-Cr-Al Alloy doped by Mo |

| Dimension | 1080 X 430 x 600mm |

| Net Weight | about 70 kg |

| Warranty & Certificate |

● One year limited warranty (Consumable parts such as processing tubes, o-rings and heating elements are not covered by the warranty, please order the replacement at related products below.) ● CE Certificate |

| Shipping package size after crating | 65x45x35" ( x2) |

| Shipping weight | 540 lbs |

| Shipping weight |

● Gas mixing controls with three floating meters(range: 0-100 ml/min, 0-160 ml/min, 0-250 ml/min) are installed on one cart that allows three types of gases to operate during heating treatment.( click picture below left to see detail specs) ● wo mobile carts are included to allow flange sliding onthe table ● Optional: for precision gas control, you may choose digital mass flow Control system instaed of float-meter at extra cost ( click picture below to see details )   3 Channels Float-meter gas control 3 channels MFC gas control (optional) |

北京壮仕科技有限公司 域名: jointec17.com

13911282924@163.com

jointec17@163.com

010-88482672 13911282924

13240057374,15910678997

> > >

> > >

> > > >

> > >